Find out how the local food distributor, Heinrich Food Pte Ltd improves its warehouse and delivery efficiencies.

Heinrich Food Pte Ltd is an established distributor of meat and seafood in Singapore. Supplying frozen food products to cafes, restaurants, hotels and food courts over the last 15 years, Heinrich Food Pte Ltd has since forged strong relationships with many of their B2B clients with their three primary promises: Consistency, Reliability, and Flexibility.

Having been in food distribution for more than a decade, the nature of the company’s business requires a sound logistic process in place and workers to carry out physically demanding jobs. Seeing the need to redesign the work processes, Heinrich Food Pte Ltd invested in an Insulated Box with Refrigeration System and Canon image RUNNER ADVANCE C5540i under the NTUC’s Employment and Employability Institute (e2i) WorkPro Job Redesign grant in 2020.

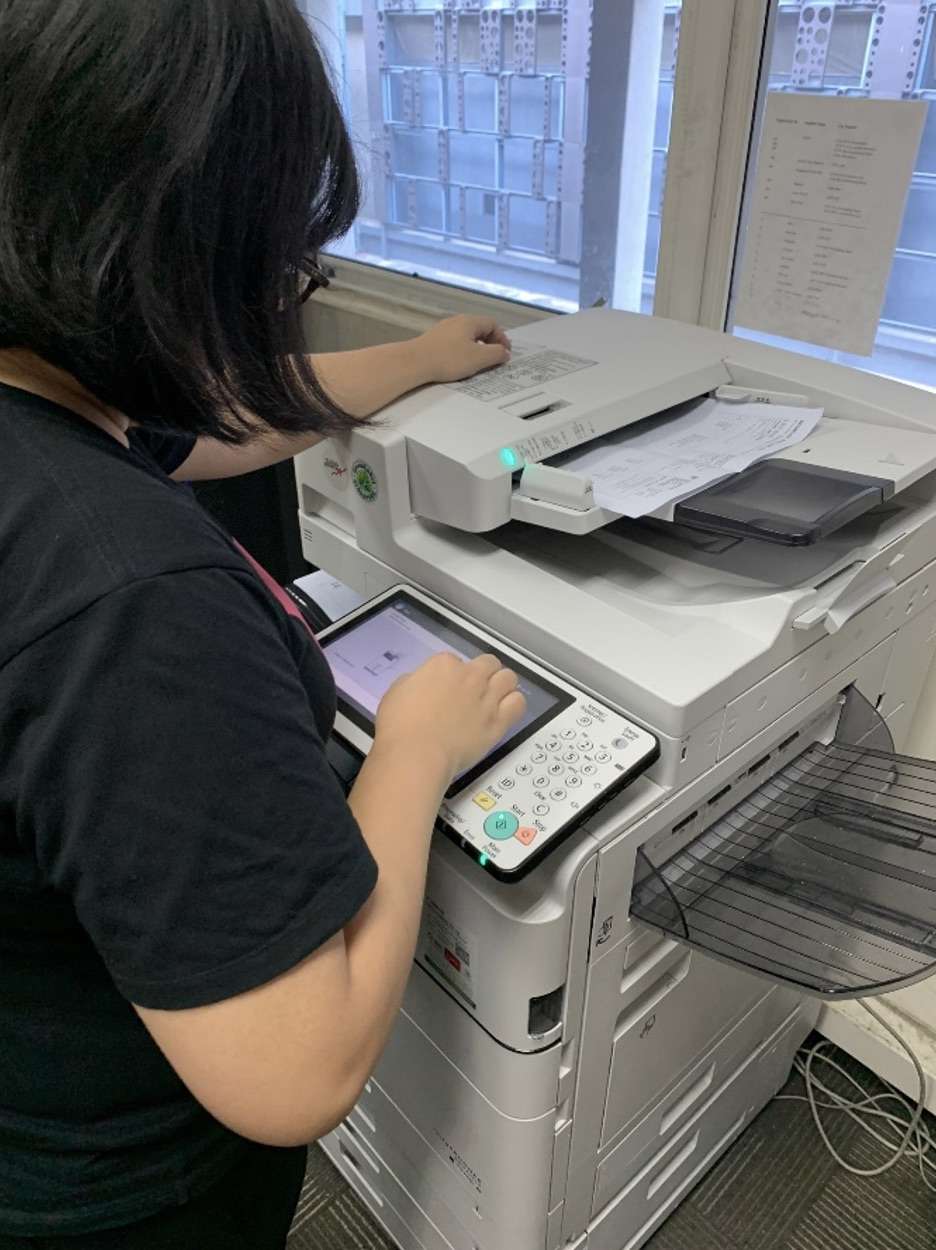

Before the incorporation of such technology into the workplace, daily operations were physically demanding and fast-moving for the older workers. Heinrich Food Pte Ltd’s delivery fleet comprising storemen, drivers and salespeople were required to report early to work every day for the picking, packing and loading of goods onto trucks manually. Additionally, the sorting process of the three-tiered coloured (white represents the customer’s copy, pink represents filing and yellow represents proof of print) invoice copies proved to be tedious and time-consuming.

With the newly commissioned Insulation Box with Refrigeration System, the workers can load the products directly onto the trucks the day before. This in turn increases productivity and reduces man hours required, thus workers no longer need to reach the workplace at extreme hours. Workers are also less susceptible to work-related injuries since the loading/unloading movement from the warehouse has been minimised.

Another piece of equipment that the company implemented is the Canon image RUNNER ADVANCE C5540i. With its high reliability and ease of operation, invoices can be printed in two-tier with QR codes from the printer along with auto stapling of the invoices together. When the drivers return from their deliveries, the QR code will be scanned by the admin staff and the invoice record will be saved into the computer automatically. This frees up time on the overall administration process and reduces the need for filing or tearing of invoices manually, making the job easier for the older workers.

With the cost-savings and increased productivity, eight of the company’s senior staff members were given a pay raise. Heinrich Food Pte Ltd also shared that they would continue to implement more of such incentives for their employees in the future.

For more information on Henrich Food Pte Ltd, visit heinrichfood.com.sg