Japanese restaurant Kiyoshi took on the challenges in its operations by embracing technology and automation.

Situated along the trendy stretch of eateries along Amoy Street, Kiyoshi Japanese Restaurant is a family-style izakaya which opened its doors right in the middle of the Circuit Breaker in May 2020. Other than a wide selection of Japanese crowd favourites like yakitori, sushi and bento sets, Kiyoshi also specialises in Inaniwa udon, a hand-stretched udon made in the Inaniwa area of Inakawa Machi; Akita prefecture.

Where Mobility Meets Efficiency

Kiyoshi spent the first couple of months of operations doing only takeaways and deliveries owing to the restrictions placed on F&B establishments to curb the spread of Covid-19. With the gradual easing of these restrictions, the team at Kiyoshi realised that they needed a Point-of-Sale (POS) solution that is robust enough to handle both the rigours of day-to-day restaurant operations, as well as the reporting and analysis of the restaurant’s performance.

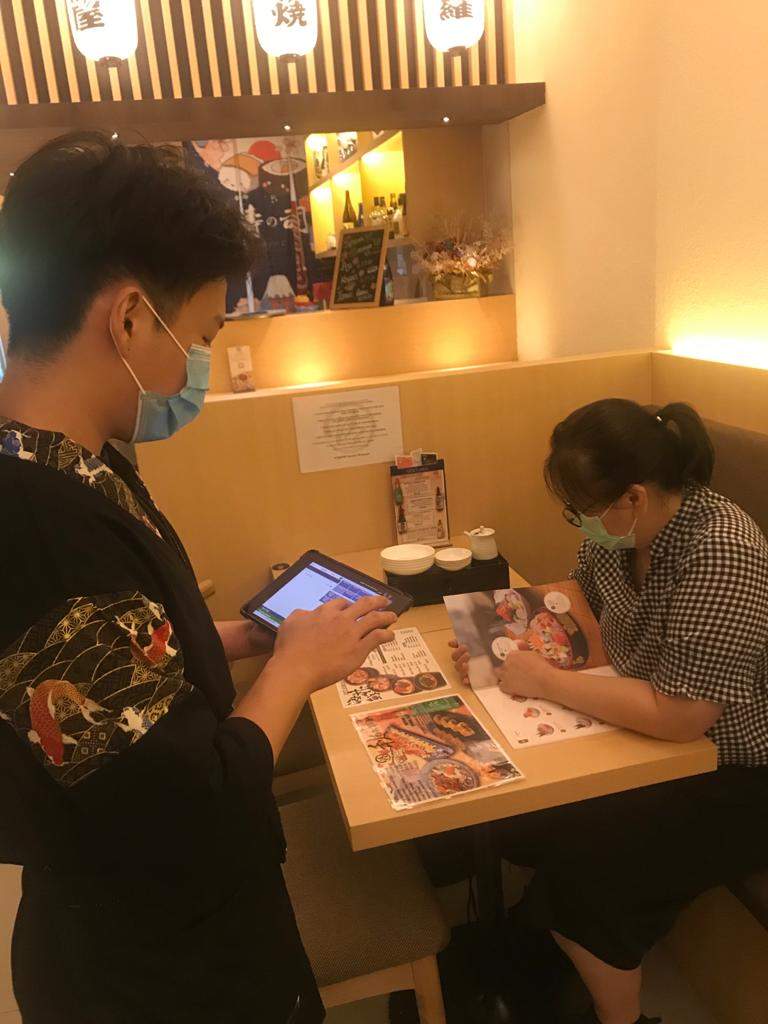

The service staff were previously taking down customer orders on loose sheets of paper before taking turns at a fixed POS terminal to key in the orders. It was a time-consuming process, especially during peak hours when precious time would be wasted waiting for the POS terminal to be available.

With the implementation of a mobile friendly POS solution, the Kiyoshi team was able to embrace the use of tablets to boost its operational efficiency. Service staff now carry the POS tablets with them as they move from table to table to take orders. The orders from customers are entered into these tablets and fired directly to the kitchen printers. The time savings helped Kiyoshi improved efficiency by 30%.

Harmonising Backend Processes

Reporting and analysis of the restaurant’s performance was also improved with the new POS solution, as the data can be viewed real-time during operations meetings without the need to manually prepare multiple Excel-based reports in advance. This allows the Kiyoshi team to concentrate on formulating strategies based on their operational data, instead of wasting time in the preparation of reports.

Procurement is a major part of any restaurant’s operations. With the purchasing and inventory module that came bundled with the POS solution, Kiyoshi is able to make light work of their procurement activities. From making purchase requisitions, recording receipt of goods to the counting of inventory items at month-end, everything is now digitalised and seamlessly integrated within a single platform.

Having the sales and cost information available from a single channel meant that Kiyoshi is now able to derive the gross margin on any menu item easily, allowing them to scrutinise the performance of their menu and make the necessary adjustments on a timelier basis. The configurable business rules and workflows within the procurement module also allows the management team to implement tighter controls while retaining the autonomy of its middle managers through the use of approval limits.

Process Redesign Through Use of Equipment

On top of the technology investments, Kiyoshi also made several equipment purchases that allowed them to redesign their work processes and improve overall efficiency. Prior to the process redesign, the cooking process for many of their dishes involved using pots and pans over an open fire. The kitchen staff had to memorise the various steps and constantly attend to the cooking process.

With the purchase of a combi oven, Kiyoshi is now able to control the food quality by standardising temperature and cooking times through their back-of-house standard operating procedure. The kitchen staff no longer need to be on standby during the cooking process and this frees up their time for other preparation tasks within the kitchen. This has helped Kiyoshi reduce their presence in the kitchen.

With an extensive menu and a seating capacity of 80, Kiyoshi has to manage a large inventory of pots, pans and crockeries. They had to employ two dedicated dishwashers to cope with the operational demands but have since been able to reduce the headcount to just a single dishwasher per session with the purchase of a dishwashing machine. In fact, they no longer need to employ a dedicated dishwasher as the use of the dishwashing machine has helped to reduce the skill barrier of the task.

The kitchen staff no longer feel that dishwashing is a tedious task and do not mind the occasional job rotation. This affords Kiyoshi greater flexibility in their back-of-house scheduling and minimises the impact of any staff turnover. Additionally, kitchen staff who have sensitive skin no longer need to worry about any potential health hazards as there is minimal contact with the dishwashing liquid while operating the machine.

The F&B industry has traditionally had its fair share of struggle with manpower issues, and this is compounded by the uncertainty brought about by Covid-19. In these unprecedented times, Kiyoshi was able to pivot its operational challenges by streamlining its existing processes through the innovative use of technology and automation. They were able to tap on the WorkPro Job Redesign initiative through the support of NTUC’s e2i and the resultant transformation has helped Kiyoshi become more resilient and ready for the challenges ahead.