It can be daunting to balance the central kitchen operations for a multi-cuisine restaurant setup, but Ho Heng appears to have found a winning formula.

Established in 2015, Ho Heng Food & Enterprise Pte Ltd operates a central kitchen supplying food products to its food and beverage restaurant brands such as Sunny Korean Cuisine, Ban Mian, Miaoxin Health Pot, Kazuki, Kent Ridge Japanese and Ha-Jun. With over 20 outlets across Singapore, Ho Heng believes in delivering affordable yet delectable and authentic flavours to consumers across its various concepts.

For Hong Hai Cheng, director of Ho Heng, the journey to automation and productivity has taken flight since early 2018. It was part of a well-thought-out plan to bring their central kitchen model to one that can be both efficient and cost effective. Ever the shrewd businesswoman, Hong researched on the various support schemes available in the market and eventually collaborated with NTUC’s Employment and Employability Institute (e2i) to execute her vision. The entire project was broken into various phases and leveraged on the combination of the Inclusive Growth Programme (IGP) and WorkPro Job Redesign grants to arrive at a comprehensive working model that primes Ho Heng for future growth and puts the company in a strong position to navigate any future headwinds in an increasingly volatile economy.

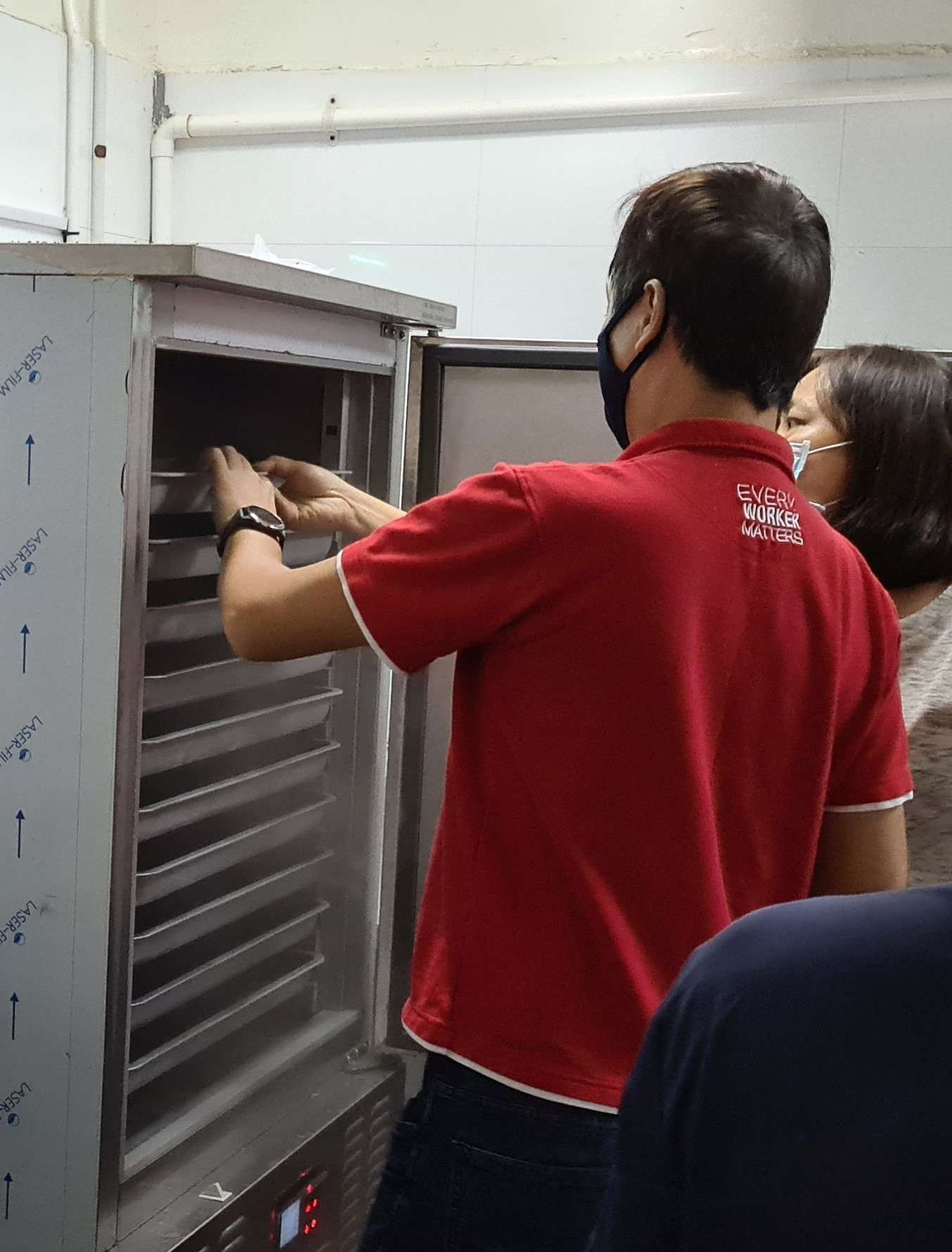

Hosting a visit by e2i’s CEO, Gilbert Tan, Hong shared the Ho Heng journey through a guided tour of their central kitchen premises in Woodlands. Other than a walkthrough of the various production zones, including the cold rooms and freezers where raw and finished products are stored, Tan tried his hand at being a production worker. The workers from Ho Heng started off the intricate process of removing the excess oil from the meat slabs before handing them over to Tan to feed into the automated meat cutter for slicing to the required thickness. The meat slices that emerged from the cutter were all of a uniform size and thickness. This quick and easy process is testament to the efficacy of Hong’s vision of a simple and easy-to-replicate production model.

Hong explained that the whole central kitchen design revolves around automation, which is why the initial phase of the project involved the installation of a host of machinery, ranging from induction cookers, deep fryers and griddles to a blast chiller that allows fresh ingredients or cooked food to undergo a quick deep freeze process to ensure maximum freshness.

Citing the example of the automatic meat mixing and tumbler machine, Hong elaborated on how the machine is able to thoroughly mix up to 100kg of meat with other ingredients within three minutes. This would have been cost prohibitive if she had relied on manual labour as she would need multiple workers working simultaneously to even come close to the same output. As recipes vary across the wide range of products that Ho Heng produces, the exact amount of time required for each mixture can be pre-programmed to requirement and her workers can now use the time saved to ensure the quality of the end product. The consistency of the product is absolutely vital to maintaining the food quality standards across the various food concepts and cuisines under the Ho Heng portfolio.

An oft-overlooked component of central kitchens is storage. Managing storage in a central kitchen context involves an intricate interplay between the production and logistical elements and stretches across raw ingredients and finished products. The cold rooms installed at the Ho Heng central kitchen have allowed the company to consolidate orders of up to 500 boxes of pickled vegetables each month instead of the previous process of processing orders on a bi-weekly basis. With the precise in-built temperature control, the pickled vegetables stay fresh longer before being delivered to the respective restaurants.

Owing to the current economic conditions, it is perfectly understandable that many restaurant chains in similar situations would choose to cut corners in their central kitchen model design due to cost concerns, which is why it requires sheer grit and determination, as well as an unerring dedication to quality to achieve what Hong did with the Ho Heng model.

Instead of lamenting the manpower issue that is the bane of every restaurant owner, forward-thinking companies like Ho Heng have learnt to innovate and leverage on technology and automation to reinvent themselves. More often than not, the productivity outcomes outweigh the initial investments, but we should not overlook the perseverance of business owners like Hong towards achieving that vision.

NTUC’s e2i acknowledges the efforts of companies like Ho Heng and are committed to walk that journey with anyone who possesses that same heart and vision. If the transformation of Ho Heng has inspired you, reach out to the team at e2i and embark on your own productivity journey today.