Discover business tips from a Singaporean-owned family business

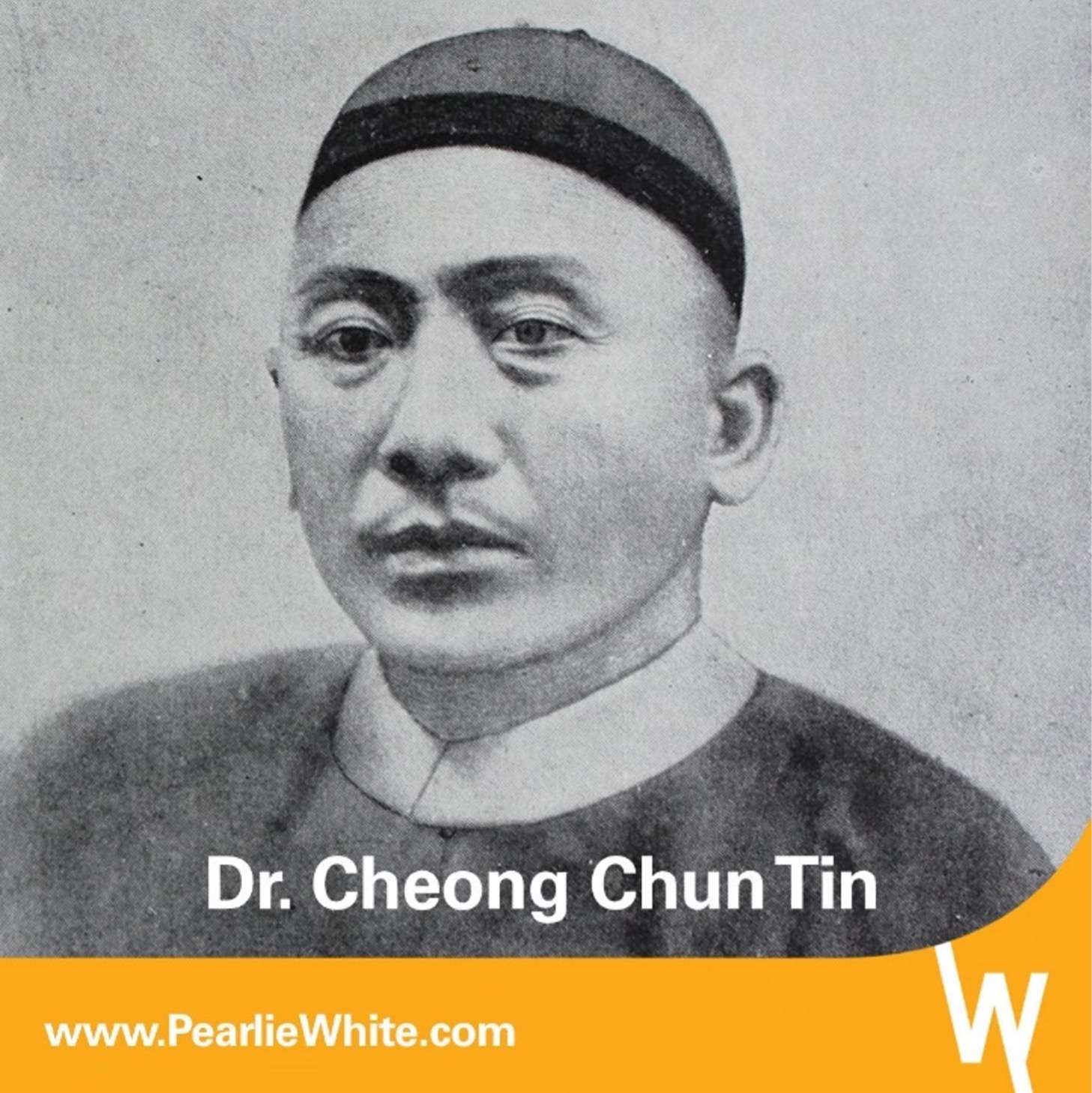

Corlison Pte Ltd traces its roots way back to the first certified Chinese practitioner of dentistry in Singapore: Dr. Cheong Chun Tin. After migrating to Singapore upon completing his training in San Francisco, Cheong set up his dental practice on South Bridge Road in 1869, which was subsequently taken over by his sons upon his death.

Almost a century later, the Cheong family started Corlison Pte Ltd, a dental products distribution business, which later founded the made-in-Singapore Pearlie White brand of toothpaste.

“We’ve been around since 1964. And we’re still a fully 100% Singaporean owned family business. Actually the most interesting thing about our company, a lot of people do not know that we own the only Singapore oral care brand and also that we operate the only oral care manufacturing facility in Singapore. We make all our toothpastes and alcohol-free mouth rinses and breath-sprays at our facility in Ang Mo Kio,” said managing director Andy Ong.

Pearlie White is popular for having no harsh ingredients such as artificial coloring and sodium lauryl sulphate. Instead, they infuse natural ingredients such as aloe, chamomile, cinnamon, myrrh and sage to help fight plaque forming bacteria, and echinacea, honeysuckle and liquorice to provide antioxidants to help soothe teeth and gums while fighting bad breath.

Other famous brands distributed by Corlison Pte Ltd include eco-friendly Method All-Purpose Cleaners made in the USA and Essano Rosehip Oil from New Zealand with certified organic ingredients. This local company also branched out into healthcare for young families with its Colief range to improve lactose digestion and relieve colic in babies.

How Corlison Pte Ltd retains its Singaporean core

Corlison Pte Ltd makes special efforts in its talent acquisition and retention efforts to retain its Singaporean core. The majority of its 85 team members (of which over 85 per cent are Singaporeans and Permanent Residents) enjoy fully flexible working hours and telecommuting/work-from-home.

Employees get to take up to five working days each year to go for training on topics of their choice with the course fees fully borne by company under its fixed annual skills-upgrading/training program.

With an in-house form of Progressive Wage Model, Corlison Pte Ltd maps out career path plans that allow team members, especially junior and executive level team members, to grow both remuneration and skills either:

– vertically (management opportunities in their own department) or

– horizontally (new job opportunities in either other existing or new departments).

It’s a testament to Corlison Pte Ltd’s efforts that its oldest employee, an accounts officer here, has been with the company since 1972, and it has been able to attract a diversity of talent across ages. 40 per cent of its team members are under 40 years old, while around 60 per cent of team members are 40 and above.

To make jobs easier, smarter and safer for its mature team members, Corlison Pte Ltd has completed three rounds of Job Redesign with NTUC’s Employment & Employability Institute (e2i) to replace manual processes with technology.

Overcoming productivity challenges with e2i

As Corlison Pte Ltd, being a company with more than half a century of operations, had manual-based processes which inevitably came with errors, it had to find a way to train its staff to handle an increased volume of customer orders as the business expanded. With e2i’s Job Redesign Grant, it embarked on three projects.

Corlison Pte Ltd first automated its electronic order entries, numbering almost 500 a day, using a software Optical Character Recognition-based system which automatically creates and keys in the orders into its Enterprise Resource Planning system. From just one order every two minutes, Corlison Pte Ltd boosted its processing speed to hundreds of orders in the same duration.

The company then automated its packing process using a cartoning machine. Team members were trained to use such equipment instead of tediously packing its toothpastes into boxes, followed by cartons and then shrink wrapping by hand.

Its third and latest project, the Warehouse Management Solution, was implemented last year with a 100 per cent increase in order processing pace and zero errors with convenient handheld scanners.

When stocks arrive, team members just use handheld scanners to barcode scan the cartons of stocks that have arrived and enter quantity received. This information simply goes straight into Corlison Pte Ltd’s ERP system. With the handheld devics, Corlison Pte Ltd did away with time-consuming processes of printing out purchasing/shipping documents, checking the name of the item on product cartons, ticking on the document to acknowledge receipt of item, before passing the document to operations team members to key into the ERP system.

To process orders, the handhelds help team members quickly locate and pick out product orders (each order can comprise of as many as 80 products) at their exact locations in Corlison Pte Ltd’s 30,000 square feet warehouse, which houses some 2,000 products.

As they pick out the products, they scan the product barcode before packing and shipping out.

Less stress = happier workers

“How e2i helped us become more productive can be summed up in one sentence – e2i helped us automate our processes with technology; which is easily understandable and consequently smoothly adopted; by our team members,” Ong shared.

“Work became much easier and stress-free, and affected team members welcomed the technology because as their order processing and stock receipt pace is higher per hour, this translated into wage increments for them. And higher wages means everyone also keen to learn!” Ong enthused.

Corlison Pte Ltd also liked working with e2i as the latter is very clear in its objectives of ensuring that whatever support it provided to companies had to in turn benefit the workers (especially the more senior of age and the lower-skilled) in terms of better remuneration, up-skilling and taking on more value-added roles.

“We can clearly say and vouch for that the team members at e2i (especially the consumer services team including Valerie Na) really took the time to understand the productivity pain points that SMEs like ours experience and also that the solutions required to solve these productivity pain pains may differ and be unique from company to company. The team really listened to us and did their best to support us,” Ong said.

Ong also adds, “We are also proud to be a U SME partner which is a clear indication of our company’s commitment to developing our Singapore core and talents and embracing not just fair but employee-beneficial work practices.”

*U SME is an initiative of the Labour Movement that seeks to support Small and Medium Enterprises (SMEs) in their business needs.

Continuing its heritage into the new norm

As Covid-19 disrupts consumer behaviours and supply chains, Corlison Pte Ltd’s prior pivot to e-commerce enabled the Singapore company to survive.

“We must re-iterate that without the projects that we implemented as a result of e2i’s support, we would not be able to conduct our peak e-commerce sales periods like 10.10, 11.11, Black Friday etc; when orders can increase from the usual hundreds per day to thousands per day. Just imagine if the projects we had mentioned earlier were not completed… how to process/fulfill orders? Unimaginable. So we would not hesitate to say that without e2i’s support, our company would not have been able to make it through the pandemic – especially during the circuit breaker period where many of our core B2B customers were closed – to be in the position we are today,” Ong elaborated.

One of the key lessons that Corlison Pte Ltd gained from Covid-19 was that it needed to diversify its sources of both revenue and goods supply more intensively. It plans to specifically expand its sales to more countries and also ensure that it is able to get supplies from more than just one country source. As Corlison Pte Ltd is in the process of doing so, you can count on it to fulfil your online order of your dental, health and cleaning essentials.

For more information on Corlison Pte Ltd, visit corlison.com