Discover how Bayfront Pte Ltd stays ahead in the game with smart technology.

Catering used to be about providing customers with quality food and offering new products that cater to the needs of the market. However, with labour constraints and increasing customer demands, how does a caterer stay ahead in this ultra-competitive business?

This is where caterers like Bayfront Pte Ltd has played their cards right. This catering company was set up by serial restaurateur Nicholas Mok in 2013 with a vision of catering quality food for functions and events.

As Mok is a food lover himself, and enjoys cooking and creating new delicacies, he set high expectations for Bayfront to provide Asian fusion cuisine for specific needs, expanding rapidly with orders from big corporate clients such as DBS and Aviva.

Bayfront has grown from strength to strength over the years with popular wishes such as its famous Curry Chicken & Seafood Spread. In 2016, they started tingkat services, and subsequently obtained Halal certification two years later in 2018. By 2020, Bayfront had expanded its menu to include Indonesian cuisine such as Ayam Penyet and Ayam Belado.

Identifying productivity gaps

Delivering freshly cooked food to customers in a timely manner is especially crucial in any catering business. However, the traditional delivery processes in catering companies can be relatively manual and unproductive.

In the past, when Bayfront was operating under its traditional delivery process, their workers had to first generate the delivery orders manually in paper form upon receiving orders via their existing order management system. The next step involved assigning the order to a driver using a simple system like Excel spreadsheet. However, this system often led to human errors in data entry and communications.

When customers called up to enquire on the status of their deliveries, the administrative staff would have to call up the respective dispatch staff to check on their location and status. The coordination between the dispatch drivers and the customers was often time-consuming and was especially dangerous to the drivers when they had to answer the calls or messages when they were on the road.

Lastly, workers handling the deliveries would have to rush back to the office to physically submit the completed delivery orders which were signed by the customers, and often resulted in the wastage of man-hours.

Enhancing business operations with digital technology

By identifying this productivity gap, Bayfront worked closely with NTUC’s Employment and Employability Institute (e2i) to explore the use of smart technology to redesign its processes and jobs.

Under e2i’s WorkPro Job Redesign initiative, Bayfront successfully implemented a delivery management system which integrated seamlessly with its existing order management system. With the implementation of this system, the jobs of its mature workers were also redesigned to be easier, smarter and safer, with higher productivity and efficiency.

Orders received in the existing order management system would automatically be ported over to the new delivery management system, removing the need for the admin staff to manually key in the order details.

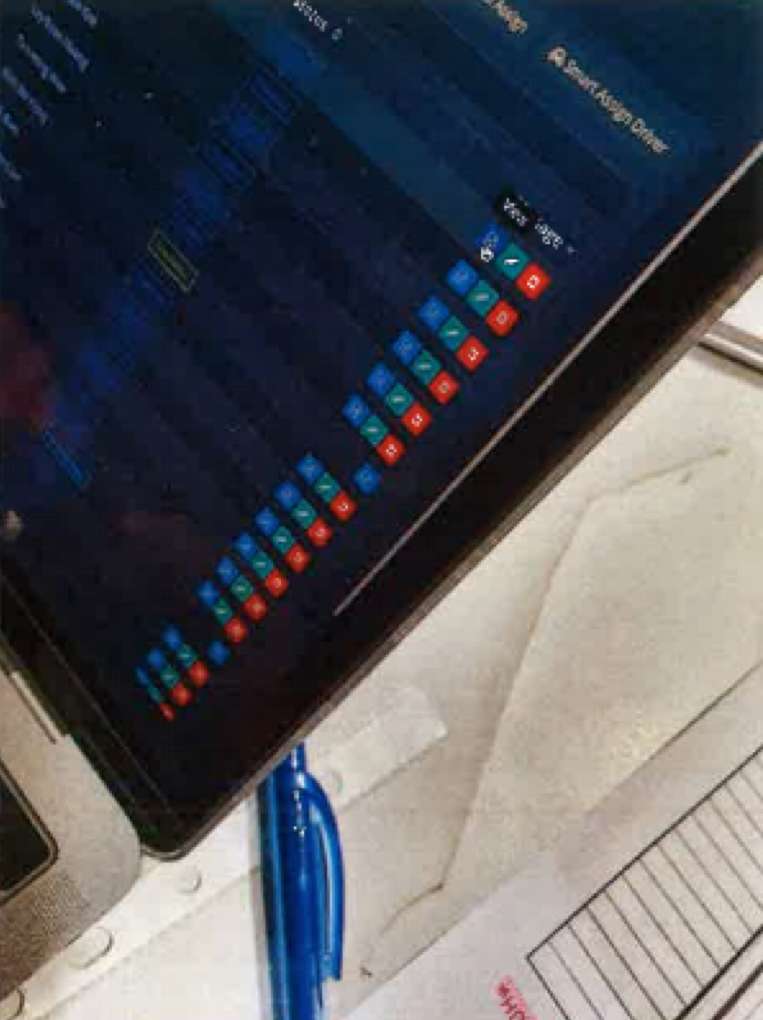

Instead, the admin staff just needs to assign the delivery to a dispatch driver based on their current locations and expected time of delivery, without the need for any physical meet-up or calls.

Once the drivers receive the orders on their mobile app, they can easily access the delivery locations using the in-built GPS map function. This saves them the hassle of keying the addresses in a third-party GPS device.

With this smart system, the tracking of deliveries is now done electronically through the system as the update of the tasks can be done via the mobile apps without the need for phone calls. Customers are also given a public URL for them to track the live status of their deliveries.

With this delivery management system, the admin and coordinator can better manage the deliveries with a full overview of all the tasks. They are also aware of any incomplete tasks that need to be assigned, hence there will not be any unattended tasks, and frustrated customers.

Saving time with the productivity initiative

Besides reducing human errors and making it easier and more convenient for both company and customers to track their orders, Bayfront has also seen significant reduction in the number of man-hours spent on manual tasks after implementing the new delivery management system.

For example, in the past, it would take a total of about 2.5 hours per day to complete the traditional processes (such as printing out physical delivery orders, filing all signed documents, assigning all orders, returning to office to submit the hard copy-signed delivery orders and planning the route to customers’ locations).

However, with the new system autogenerating delivery orders and updating task progress in real time, the time needed to complete the processes in total has been significantly reduced to just three minutes per day.

Besides having more time to rest, staff can now spend their time on performing higher-level tasks as well, and several mature workers, whose productivity rose due to the system, received a wage increment.

With its local system easier, smarter and safer for its workers, Bayfront is better poised to cater to a new norm of increased deliveries due to the Covid-19 pandemic.

Moving forward, Bayfront intends to introduce a franchising model whereby it will supply the ingredients to interested franchisees, further expanding the company’s brand and market share.

For more information on Bayfront Pte Ltd, visit http://bayfrontfood.sg/