Mr Alan Tan grew up in the footsteps of his grandfather who managed a chicken and pig farm back in the 1960s, and his father who founded a roasted meat eatery in the 1980s. Nurtured under their influence, Alan developed a profound interest in culinary art and set his heart on a career in the F&B industry from a tender age.

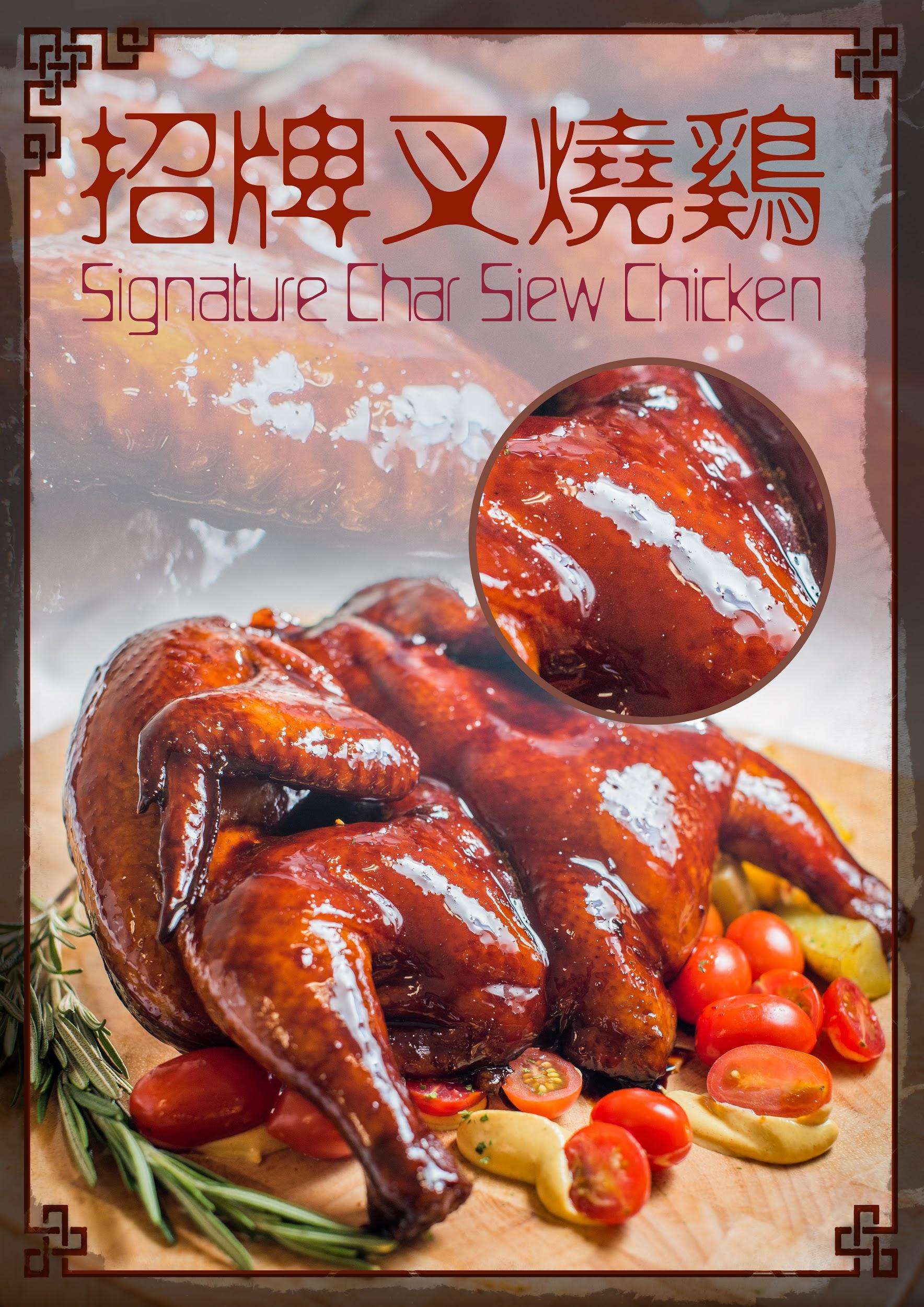

In 2016, Alan established Asian Rotisserie, a hot food-deli counter specialising in freshly-roasted traditional meat products like Hong Kong-style Roasted Duck, Roasted Pork Belly, BBQ Char Siew and their in-house Signature Char Siew Chicken. To date, the company has nine retail counters operating island-wide at selected local Cold Storage and Giant Supermarket outlets.

Streamlining Factory Work Processes

With nine outlets to distribute their products to, Asian Rotisserie’s food factory handles food preparation processes like meat-tenderising, marinating, as well as the cooking and packing of sauces on a large scale every day. These processes were initially carried out manually by workers, where there was a limit to how much each worker can mix in one session. Hence workers had to repeat the processes to produce in batches, which was both laborious and time-consuming.

Seeing the need to redesign the work processes, Alan engaged the assistance of NTUC’s Employment and Employability Institute (e2i). Under e2i’s WorkPro Job Redesign grant, which provides support to companies to remodel their work processes to make them safer and smarter for older workers, Alan was able to purchase several equipment for the food factory to enhance the production processes.

Automatic Tumbler Machine

The Automatic Tumbler Machine automates the mixing process of meat. Settings such as duration and speed of mixing can be pre-programmed for ease of selection during operations. With the machine’s large mixing capacity, more products can be mixed during each session. This allows for higher productivity, and product consistency.

The Automatic Tenderiser Machine

The automatic tenderiser machine automates the tenderising process of various types of meat. After the process, the products are rolled along the attached conveyor belt to be collected for packing easily.

High Concentration Sauce Packing Machine

With this automation, sauce from the large cooking pots are automatically portioned into the required volume and sealed into sachets, making the process safe and easy for older workers.

A Gratifying Outcome

With less repetitive work and more efficient work processes, Asian Rotisserie charted a decrease in man-hours by at least 30%, as well as a significant productivity gain. While many companies were greatly affected by the Covid-19 economical impact, Asian Rotisserie remains unaffected with its streamlined work processes and high production levels brought about by the new equipment.

The company was also able to share its productivity gains through increments and bonus to all impacted workers.

Future Prospects In Automation

Through the use of more modern technology equipment, Asian Rotisserie seeks to further enhance their food production workflow. They aspire to provide a safer working environment for their staff, and increase productivity, which in turn enable Asian Rotisserie to continue to provide quality food to their consumers at an affordable price.

For more information on Asian Rotisserie, please email asia.rotis@gmail.com

Asian Rotisserie outlets are located at:

Cold Storage Supermarket:

1 Sengkang Square, #B1-25, Compass One Shopping Mall, Singapore 545078

10 Tampines Central 1, #B1-01/02, Tampines One Shopping Mall, Singapore 529536

1 Woodlands Square, #B1-31/32/33, Causeway Point, Singapore 738964

205 Hougang Street 21, #01-133/135, Heartland Mall, Singapore 530205

1 Bukit Batok Central Link, #01-01, West Mall, Singapore 658713

68 Orchard Rd, #B2-15/16, Plaza Singapura, Singapore 238839

930 Yishun Ave 2, #B1-06/07 Northpoint City, Singapore 769098

23 Serangoon Central, #B2-44/45, NEX Shopping Mall, Singapore 556083

Giant Supermarket:

2 Jurong East Street 21, IMM Building, #01-100, Singapore 609601