City Foods Industries specialises in the manufacturing of satay products and barbecue items. Better known as City Satay, the company started its business operations in May of 1987 from a small shop in Bedok. Back in the day, the satay meat was manually marinated and skewered by hand. And as the business gradually expanded, production was first shifted to Tanjong Katong then subsequently to its current location, in Bedok North, in order to meet the increasing demand.

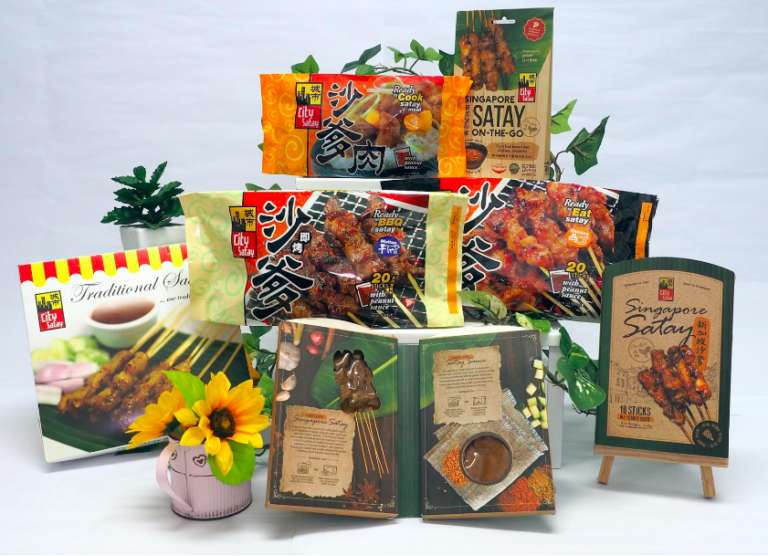

Inspired by Singapore’s multicultural spirit, the humble stick of satay is the product of an amalgamation of Asian spices. The freshly made marinade first flavours then tenderises the meat, which are slowly skewered on bamboo sticks before being grilled to perfection. Commonly eaten with peanut sauce, City Satay’s skewers of happiness have been enjoyed by generations of Singaporeans and tourists alike.

The company’s production lines are already highly-automated – having previously made strategic investments into meat-cutting, marinating and skewering machines that help eliminate manual production work and increase efficiency. Not one to rest on its laurels, City Satay continued to revamp its production methods and partnered with NTUC’s Employment and Employability Institute (e2i) to further enhance the packaging efficiency of its products through the WorkPro Job Redesign scheme.

The older workers on City Satay’s team used to spend long hours repeatedly pressing the air out of each satay packet manually before sealing them. This process is now automated with the touch of a button through the purchase of a vacuum packing machine. The machine draws the air out of each packet more thoroughly and at a much greater speed. No worker, no matter how skilful or efficient, would be able to deliver a similar level of output.

Towards the end of the production cycle, the introduction of a multifunction blast freezer allows the older workers to immediately store the warm final products for deep freezing. Previously, the cooked products needed to be cooled down sufficiently before they can be frozen. Workers had to constantly monitor the conditions at the food cooling station to ensure that the food is properly cooled down before transferring them to the freezer. This whole process is tedious and is susceptible to cross contamination.

With the new multifunctional blast freezer, the entire process only takes up to two hours, which becomes a huge efficiency gain for City Satay – given the long waiting time of the previous conventional method. With this free time, older workers can now be deployed to perform other value-added tasks within the production line.

After embarking on the automation of their packaging process, City Satay is now able to triple its output with half the man hours. As a result, the company has committed to share the productivity gains with its older workers. And each of their five eligible older workers have received a wage increment.

City Satay may be a small enterprise, but their vision is anything but. The company has designed its production lines with hygienic facilities and processes to meet the ISO 22000 Food Safety Management System standards and requirements. There is also a strong focus on product innovation and continuous collaboration with institutes of higher learning to develop new products that are healthy and suitable for all ages. With these certification and innovation efforts, customers of City Satay can be assured that the products they purchase would be of the highest quality and consistency.

The achievements of City Satay are a testament to the power of innovation. The creative redesign of its processes to blend in the use of automation has helped to improve productivity significantly without breaking the bank. Hopefully this would inspire other small and medium enterprises out there to take that first step towards their own productivity journey.