Established in Singapore by a team of entrepreneurial individuals in 2014, Food Fresh specialises in the manufacturing and distribution of ready-to-serve artisan pastry. Their customers range from cafes, bistros, fine dining establishments and hotels, to airlines and marine offshore clients.

Centred to provide their customers with the convenience of their ready-to serve products, the company also provides customisation of products for their customers. With their quality products and unique service, the company has since established itself as Singapore’s leading and finest B2B wholesale supplier of pastry and bakery products.

Food Fresh’s products range from their in-house brands: Trelicious, Bel Epi, Frozen Wonders and Brioche King, to Britain’s favourite baked goods brand: Warburtons.

In 2017, they were appointed as Singapore’s authorised distributor of the Vandemoortele Group. Vandemoortele is a leading European food group that manufactures and sells high-quality food products in two main business lines: One in Frozen bakery products, and the other in margarines, culinary oils and fats.

Changes in View of Furtherance

Following their new distributorship, Food Fresh commissioned their newly constructed factory at JTC Food Hub @ Senoko the following year. They also invested in their own delivery fleet of refrigerated trucks to ensure that their products reach their customers in pristine condition.

The company has always prided itself of its stringent food safety standards when it comes to production and product logistics. Since its commissioning in 2018, the factory has obtained the FSSC (Food System Safety Certification) 22000 certification – the highest Food Safety Management Standard. They also obtained the “A” grade from Singapore Food Agency for five consecutive years.

All the hard work of adhering to strict production standards require dedicated manpower. Hence the company has been actively sourcing for production automation, so as to free up precious manpower to improve labour efficiency. They also took into consideration that older workers in the factory may also find it challenging to keep up with the increase in productivity demands.

Therefore with the assistance of the Employment and Employability Institute (e2i), the company purchased the automatic dough divider and ultrasonic food cutting machine to redesign the production processes to be easier, safer and smarter for their older workers. The improvement in productivity brought about by the machines also enabled the company to disburse increments to their workers.

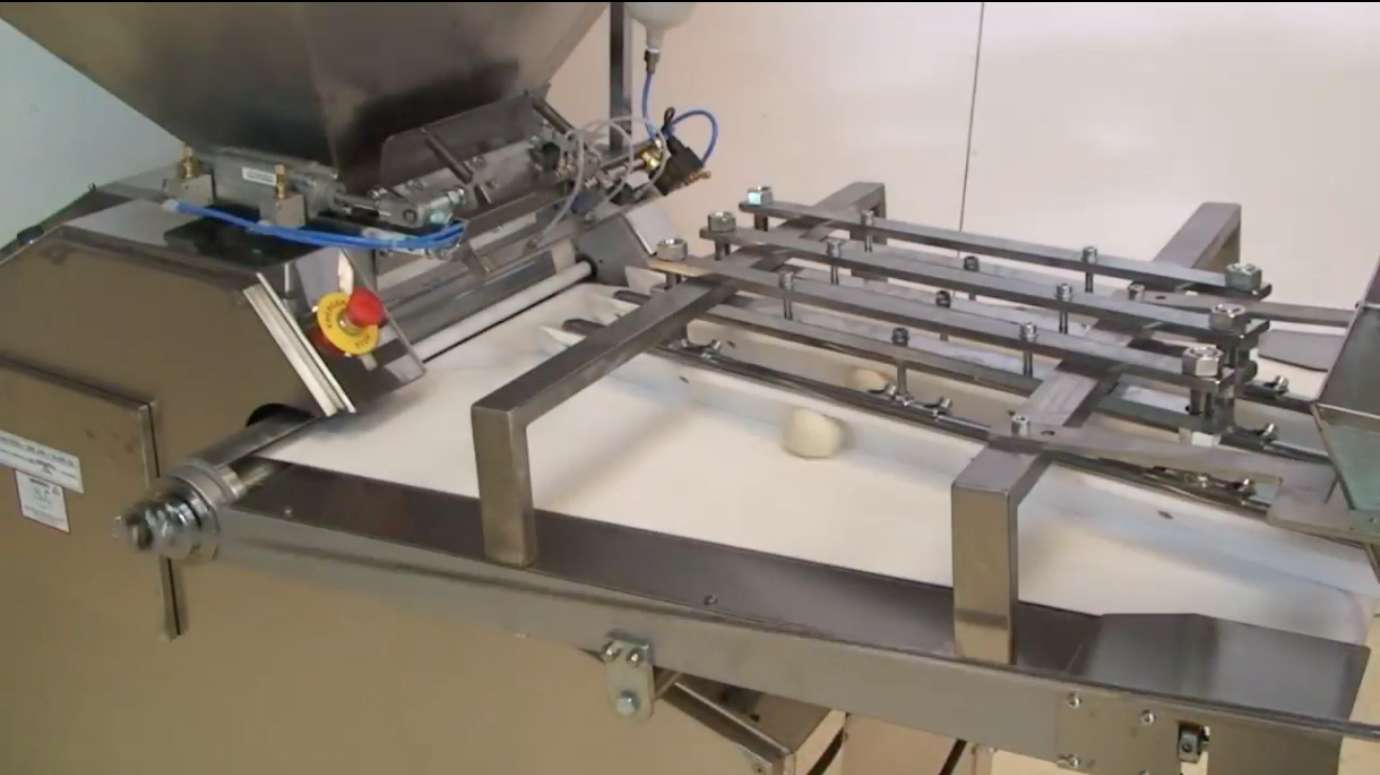

The Automatic Dough Divider

The automated dough divider allows the dough’s dimensions and weight to be easily adjusted to the required size. Compared to the kneading (rounding the dough) and dimension adjustment by hand previously, the time taken to shape the dough is reduced by approximately 30%. The divider also comes with a piece counter that allows the user to select the number of pieces to be divided in each production. This eliminates the task of workers counting the doughs manually, hence reallocating labour to other tasks. Other than dividing the dough, the machine also oils and dust the dough with flour, which combines the steps of dividing, oiling and flour dusting, all into one. This further decreases the time taken for dough production.

The Ultrasonic Food-Cutting Machine

Programmed to slice whole cakes according to the required slices or sizes, the cutting machine prevents older workers from accidents when handling cutting tools, and increases the ease of cake slicing. Workers now require only half the time to cut one whole cake, and each slice is marginally equal in size. The machine can also cut cakes of different shapes and sizes. Previously, brittle cakes that fell apart when cutting would be discarded. Hence the machine reduces production wastage as they work well on brittle and soft cakes with their zero pressure cutting process.

The Pursuit for Technological Evolution

Food Fresh have their future steps set in product enhancement and innovation for the years ahead. Always a step ahead in adopting the latest technology, they hope to come up with further product advancement, just like Vandemoortele’s Bake’Up technology, where Bake’Up pastry is only 60% of their original size when frozen. Their use of Rapid Blast freezing technology in their production is another such example of technology’s contribution in the food production sector for ensuring the highest standard of production. With their success so far, Food Fresh will surely not disappoint, and we can look forward to being amazed by their next round of innovation.

For more information on Food Fresh Pte Ltd, please visit foodfresh.com.sg