Founded in 1989 by Mr Ng Chai Huat and his wife Madam Ong Chu Eng, heritage brand Swee Heng started as a tiny shop churning out handmade pastries in Jurong East. Their youngest son Eric Ng and his two siblings (Jason Ng and Poh Choo) are the ones running the show these days in their role as the Executive Directors of the company.

In the last 30 years, Swee Heng has seen many similar businesses come and go, but it has managed to weather the storm and grown from strength to strength. One of the key business decisions was embracing the use of technology and automation.

Swee Heng gradually grew from a humble outfit with 10 employees to a household name with more than 60 retail shops. To keep up with this growth, the company had to pivot to a central kitchen operating model and even traded its original central kitchen in Senoko Crescent for a larger 6,000-square-meter facility in Senoko Avenue in 2017 to further scale up its production capacity.

Swee Heng has been a bold adopter of technology and automation when it set its sights on transforming its business. With Eric at the helm, they fully embraced the Technology skillset of the Worker 4.0 framework by implementing an Enterprise Resource Planning System to automate back-end business processes.

As part of an overhaul of its antiquated manual processes, the new system can consolidate the orders from all of Swee Heng’s retail outlets in real time and allocates them to the relevant production units in the central kitchen. Once the system stabilized after going live, there were no longer any issues due to miscalculations or miscommunications that would impact the fulfilment of daily orders.

Over the years, Swee Heng has also built up a strong relationship with NTUC’s Employment and Employability Institute (e2i). The company even teamed up with e2i to launch the Heritage bread and cakes series to commemorate Singapore Bicentennial. Known as the HaloSingapo series, it comprises buns and cakes that incorporate local flavours that Singaporeans grew up loving, from chendol to nasi lemak and even rendang. They were made available at all Swee Heng retail outlets and were a roaring success with the local crowd.

Honouring the Classics

Chef Chai Poh Lo is the Production Executive Chef at Swee Heng and doubles up as their Research and Development (R&D) lead. Chef Chai built up a reputation as an innovative pastry chef through his 30 years of hotel, casino, airline, and catering experience. He has also represented Singapore in multiple international culinary competitions.

One of the toughest challenges of Chef Chai’s role is to ensure that he preserves the traditional flavours while improving the visuals for today’s market. And if that was not challenging enough, he needs to also maintain the consistency of the output while increasing productivity. This is certainly no mean feat, especially if you consider how fickle-minded consumers are these days and the fact that the Swee Heng central kitchen is supplying its 60-over retail outlets island-wide.

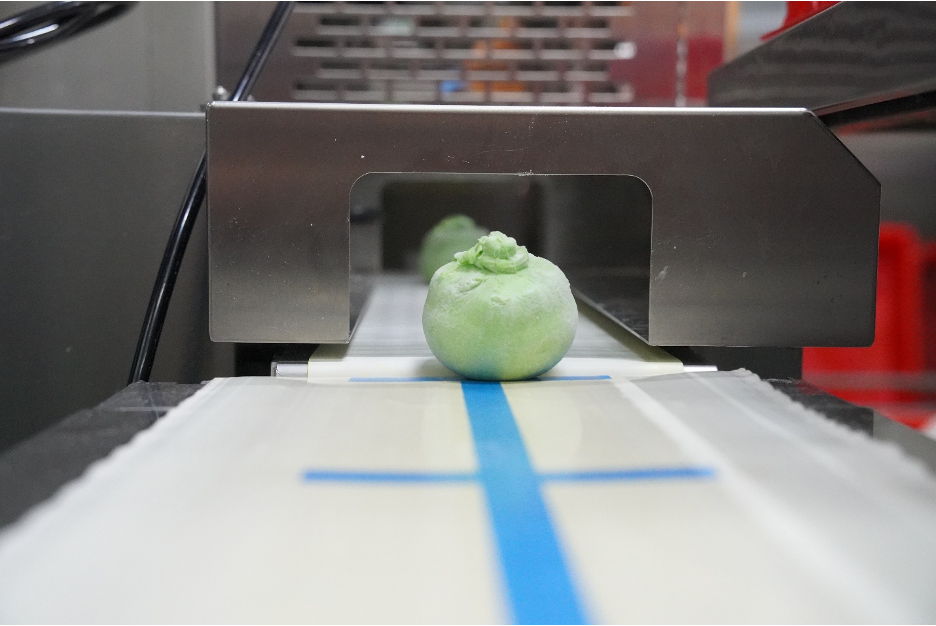

The Pandan Coconut Bun is a Swee Heng classic and its best-selling item. It has a distinct pandan fragrance with a thick coconut centre surrounded by a layer of fluffy bread.

The Pandan Coconut Bun truly epitomizes how far Swee Heng has come in its transformation journey. It was originally produced by hand through the manual filling and shaping method. By its estimation, Swee Heng’s production workers could produce 200 pieces per worker every hour. While this level of output is by no means shabby, there was always the risk of overfilling as the process was done fully by hand.

Since the introduction of the encrusting machine, Swee Heng has been able to churn out 1,200 pieces of Pandan Coconut dough per hour consistently. The encrusting machine essentially automates the hand shaping process by enabling the filling to be deposited accurately. Once the filling is set, the machine wraps the dough flawlessly around the filling in one swift motion.

By adopting the encrusting machine, Swee Heng was able to resolve its problem of consistency without affecting the taste and quality of its best-selling product. This is the perfect example of how innovation and technology if adopted skillfully, can be a driving force and not a deterrent. This truly exemplifies the Technology and Adaptive skill pillars of the Worker 4.0 initiative.

Another Swee Heng crowd favourite is the Classic Otah Bun. It has strips of savoury spicy otah floating atop a soft, fluffy bun. The heat on the otah is nicely balanced with a cool mayonnaise dressing and shavings of parmesan cheese. You would also get hints of the panda flavour from the pandan leaf sleeve encasing the bun. Taste, texture, colour and smell – your senses are bound to be tingled with your very first bite!

As the toppings of the Classic Otah Bun are assembled by hand, the skills of the production workers are challenged as they need to be mindful of the uniformity of the topping so that the intended taste of this Singapore-flavoured bun is not altered.

Defying The Odds and Coming Out on Top

From the early days of convincing workers that their livelihood is not affected by the introduction of machinery and automation, Mr Eric Ng has managed to weather all storms to bring Swee Heng to where it is today.

If you were to visit the central kitchen and observe for yourself the clockwork precision with which the various production lines operate, you will come to appreciate the magnitude of their achievement.

It all started with a man’s vision of the future – a highly unpopular one that involved machines, but he has managed to convince his detractors that the taste of tradition can be preserved even with the help of automation.