You might be thrown off slightly by the French-sounding name, but make no mistake, Montreux Patisserie is a true-blue Singaporean company.

Their story began when Chef Lee Lay set up his family bakery in 1995 along East Coast Road. Over the years, Montreux Patisserie has evolved into one of Singapore’s most successful pastry manufacturers. It currently occupies a 51,000-square-foot food manufacturing facility that employs over a hundred bakers and cooks to churn out its repertoire of authentic French pastries.

Chef Lee Lay is an award-winning international chef with over 40 years of experience, but he has since handed over the mantle to his son Lee Chit Shung, who is the current Managing Director of Montreux Patisserie, to carry on the family legacy.

Despite its humble beginnings, the ambition of Montreux Patisserie has always been to become a market leader and Chit Shung has set that gameplan in motion by painstakingly building a culture of innovation and influencing his team to embrace the use of machinery and automation to improve productivity.

The company has always worked in close collaboration with NTUC’s Employment and Employability Institute (e2i) to future that ambition. From getting industry connections to gain access to a wider range of suppliers and equipment vendors to re-designing existing work processes to improve the work environment and safety of its employees, Montreux Patisserie has always been able to count on the competent team at e2i for their support and professional advice. While the government funding has helped the company from a financial perspective, it is the strong bond that it has built with e2i that truly defines this partnership.

The positive thing is that Chit Shung is not alone on this journey and he counts his Production Manager – Chef David Tey Chee Sien, as one of his key comrades.

Destined to Be a Baker

Chef David comes from a family of bakers and has been baking since he was 11. He began learning the ropes by working part-time at his relatives’ bakery. Now 40 years of age, Chef David brings a wealth of experience to Montreux Patisserie and has also been instrumental as an advocate for innovation.

The spirit of innovation has been one of the defining factors of Montreux Patisserie’s company culture, and it is also one of the hardest to cultivate. One of the more creative ways that the company has come up with is to leverage the various festive seasons within each calendar year to motivate and push the team to think out of the box. And it is not restricted to the usual ethnic festivals; there are other opportunities like the Singapore F1 Grand Prix and even bespoke products for customers.

Chef David would normally take the lead on such occasions to set the tone and inspire the rest of the team. He would often stir up interest in new and interesting trends based on his research and challenge the team to develop those ideas or come up with their unique spin on things. He makes it a point to always involve all the team members, from tasting to providing feedback and ideas for further improvement.

Even in situations where they need more experienced support to troubleshoot any product-related issues, Chef David can always reach out to Chef Gerhard, who acts as a consultant to Montreux Patisserie.

Technical Competency as A Foundation

Aside from innovation, the team led by Chef David excel at the technical aspects of baking. The Technical skillset is recognised as a key skill pillar under the Worker 4.0 framework, and it is not hard to see why. With sound fundamentals, it is often easier for the team to experiment with new ideas knowing that they would eventually have the technical competency to bring the idea to fruition.

Three creations highlight the technical excellence of the Montreux Patisserie team – Provence Focaccia, Bakka Nutella and Pecan Banana Sticky Bun. All three are timeless classics in the company’s product list and it is easy to appreciate why after knowing how each of them is created.

The Provence Focaccia requires a long fermentation process of up to 24 hours to improve its aroma and accentuates its airy texture. The trick is to allow the yeast-cultured dough, better known as the poolish, ample time to develop into a bubbly and voluminous mixture. The long fermentation also helps to draw the most flavours out of the ingredients and the infused oil drizzled on top gives it a fragrance that we have come to expect from a Provence Focaccia.

Bakka is a Jewish pastry made from a rich brioche dough, usually with a cinnamon or chocolate filling. The Montreux Patisserie version has a local spin to it, as the star of the show here is Nutella.

The Bakka Nutella is normally produced in big batches. To execute them in such large volumes, temperature control during production is absolutely crucial. The dough is first frozen in a blast freezer and maintained at zero degrees celsius before it is sheeted, filled and braided.

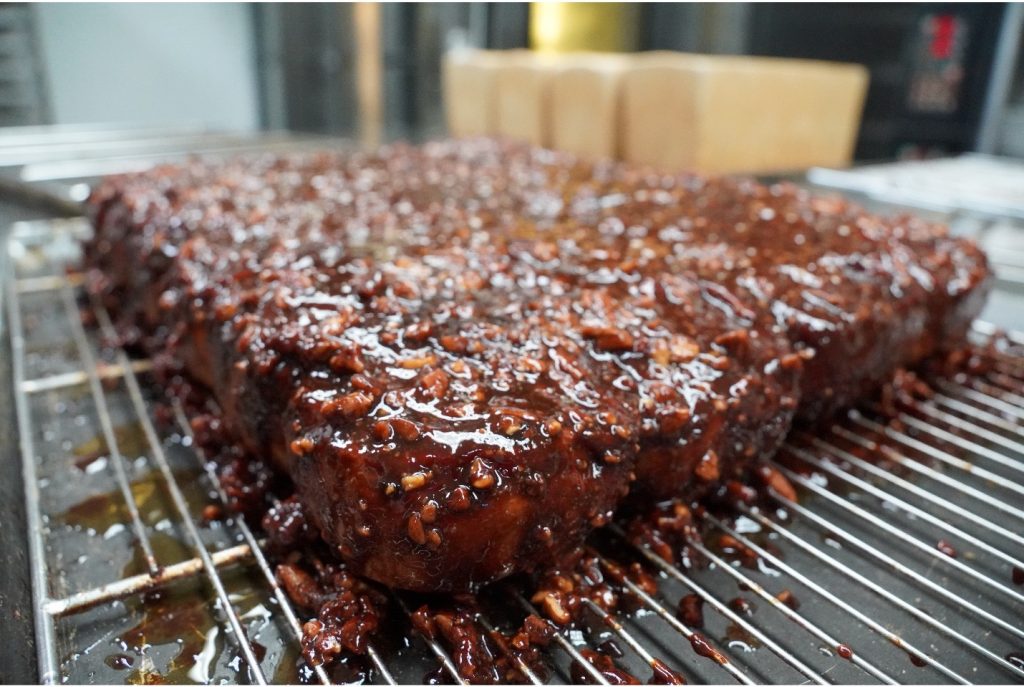

The base ingredient of the Pecan Banana Sticky Bun is the caramel, which first needs to be cooked before roasted chopped pecans are added to it immediately before the mixture solidifies. This will go on to become the layer of topping on the sticky bun.

The entire topping mixture is then set in the blast chiller to harden. Similar to the Bakka Nutella, the dough of the sticky bun needs to be blast frozen and maintained at zero degrees celsius before it is sheeted, filled and shaped. Jaggery, a dark brown sugar is selected for its fragrance and that is rolled up in the dough for the flavours to be fully infused during the baking process.

The shaped dough is then placed on top of the chilled topping before baking. The heat from the oven melts the caramel topping, creating a decadent and gooey layer, hence the name stick bun.

Slowly but Boldly

Around 30 years ago, Chef Lay Lee lay down the first foundations for Montreux Patisserie, and his son Chit Shung managed to elevate the company to a whole new level, with a little help from his friends at e2i. His bold ambitions have never wavered as there is a deep trust in the company’s mastery of technical baking skills, which is ably supported by an openness to innovate and embrace the use of machinery and automation.

The path to greatness is a long one, but Chit Shung knows the winning formula and is steering his team in that direction.